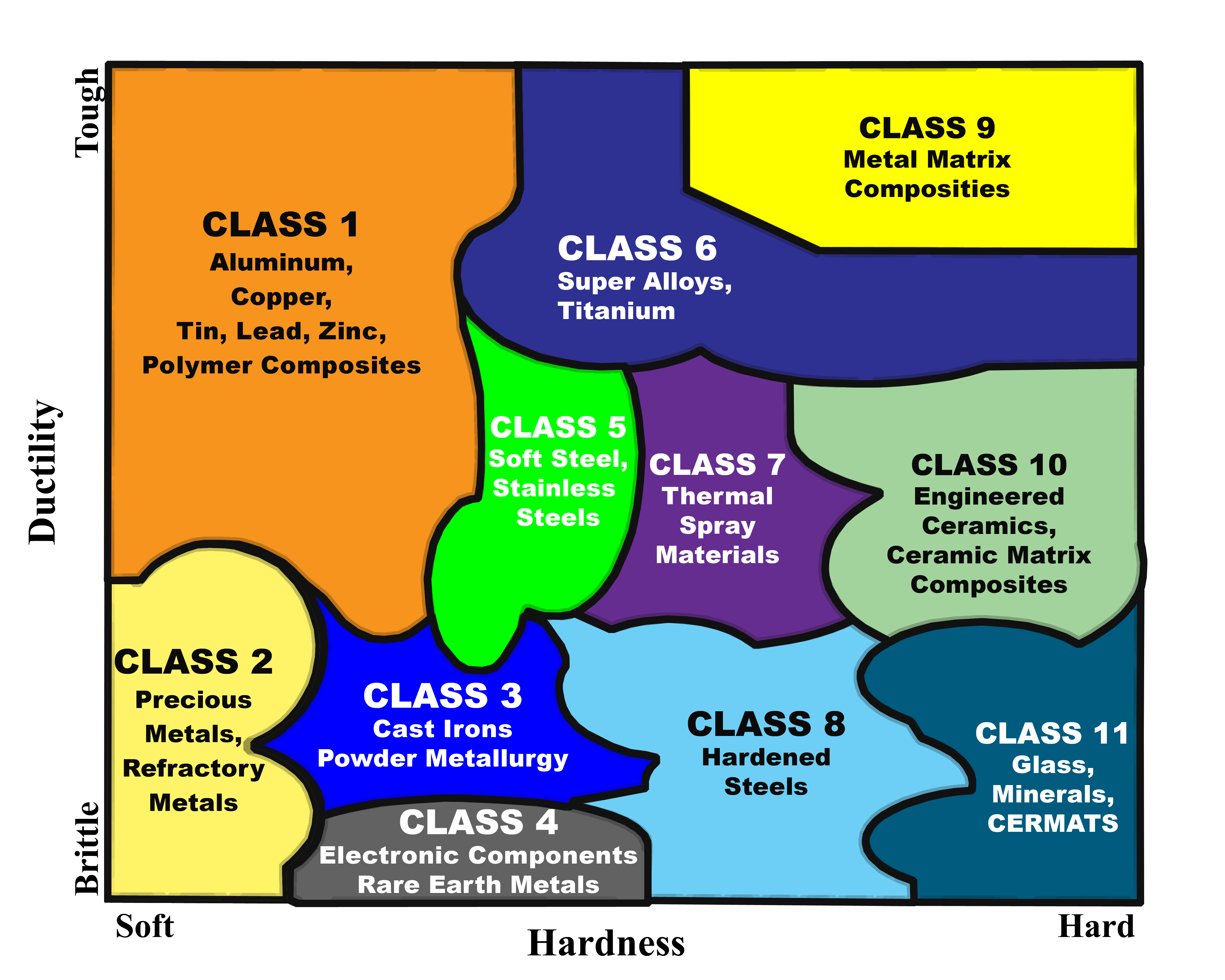

Class Overview Table

|

CLASS-1 (Soft, Ductile Materials) |

|

|

CLASS-2 (Very Soft, Low Ductility Materials) |

|

|

CLASS-3 (Lower Ductility Metals) |

|

|

CLASS-4 (Soft Brittle Non-metals) |

|

|

CLASS-5 (Medium Hard/Ductile Metals) |

|

|

CLASS-6 (Tough, Hard Non-ferrous Metals) |

|

|

CLASS-7 (Thermal Spray Coatings) |

|

|

CLASS-8 (Hardened Steels) |

|

|

CLASS-9 (Metal Matrix Composites) |

|

|

CLASS-10 (Engineered Ceramics) |

|

|

CLASS-11 (Very Hard Brittle Materials) |

|