Magnetic Polishing System

PACE Technologies’ magnetic system streamlines sample preparation by combining magnetic-backed pads and disks with durable magnetic baseplates. This flexible setup allows for quick changes and reliable flatness, all while maintaining precise control across both rough and final polishing stages. Compatible with alumina, diamond, and colloidal silica suspensions, our magnetic system is optimized for high-throughput metallography labs and research facilities.

Why Use Magnetic Polishing?

- Consistent Results: Stable adhesion improves contact uniformity and repeatability.

- Versatile Sizes: Available for 8", 10", 12", and 14" platens.

- Pair with Magnetic-Backed Pads, SiC Papers, or Diamond Disks: Full range available for rough grinding through final polishing.

Shop Now:

Learn More:

More Resources:

Introduction

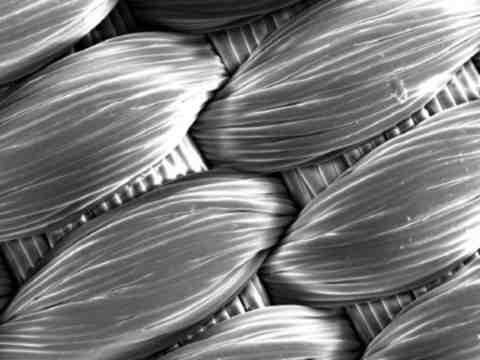

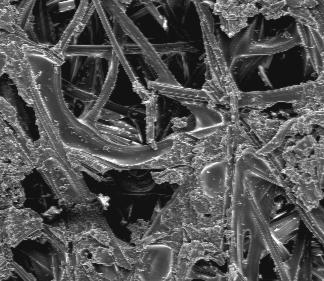

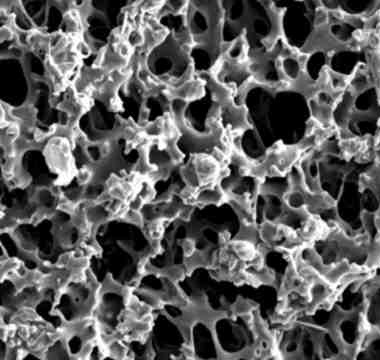

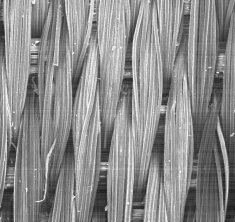

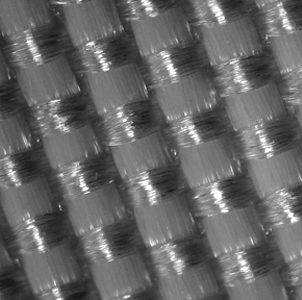

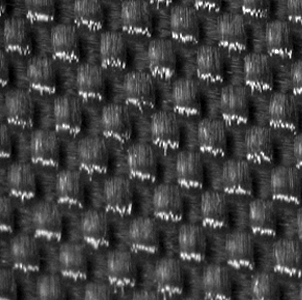

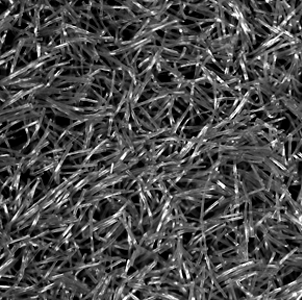

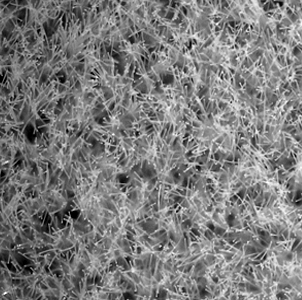

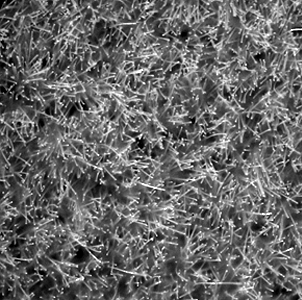

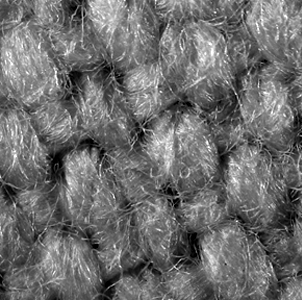

Selecting the right metallographic polishing pad is essential for achieving precise, repeatable surface finishes in sample preparation. Pads vary in nap height, backing type, and material composition, which impacts abrasive support, flatness, and edge retention. Low-napped pads paired with diamond abrasives are used in rough polishing to remove grinding damage, while high-napped cloths and fine abrasives like alumina or colloidal silica are ideal for final polishing. Choosing the correct pad minimizes artifacts such as edge rounding, relief, and smear, ensuring accurate microstructural analysis.

Polishing Pad (MAG) Selection Guideline

Process Description

Polishing typically involves two stages: rough and final. Rough polishing removes deformation from grinding using low-napped pads and polycrystalline diamond abrasives. Final polishing uses high-napped cloths and finer abrasives such as alumina or colloidal silica to eliminate minor defects.

Using magnetic-backed pads simplifies transitions between stages and ensures consistent flatness due to firm, uniform adhesion across the platen. This stability minimizes polishing artifacts and helps maintain process control across multiple specimens.

Excessive polishing can cause artifacts like relief, edge rounding, and smear, so polishing time should be minimized.

Minimizing Polishing Artifacts

To reduce edge rounding, phase relief, smear, and grain pull-out:

- Minimize sectioning and grinding damage upfront

- Use the finest effective abrasive at each stage

- Ensure polishing plates are flat (≤2.5 µm runout for 8" plates)

- Use magnetic systems to maintain stable, reusable pad alignment

Recommended Procedures

- Place magnetic-backed pad on a clean magnetic baseplate

- Pre-charge pad with abrasive suspension, paste, or powder

- Apply appropriate lubricant

- Begin polishing with reduced force to avoid tearing

- Clean specimen and pad during the last 10–15 seconds

- Wipe both pad and baseplate dry before storage to avoid corrosion

Troubleshooting

| Symptom | Cause | Solution |

|---|---|---|

| Coarse Scratching | Contamination on polishing pad | Replace pad with a clean magnetic-backed version |

| Tearing of Pad | Excessive force or poor lubrication | Reduce force; improve lubrication and ensure full pad contact on magnet |

| Pad Slipping or Lifting | Contaminated baseplate or warped pad | Clean baseplate surface thoroughly; ensure pad is flat and undamaged |

| Excessive Relief / Edge Rounding | Improper pad selection or prolonged polishing | Use suitable nap pad; minimize final polish duration and verify flatness |