Polycrystalline Diamond Polishing

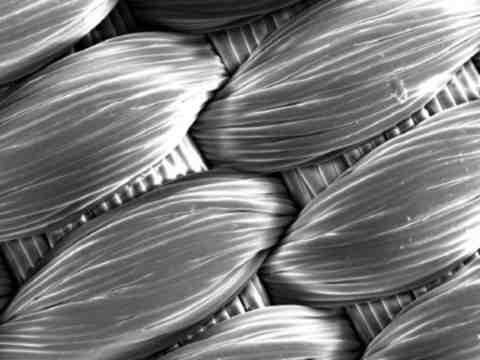

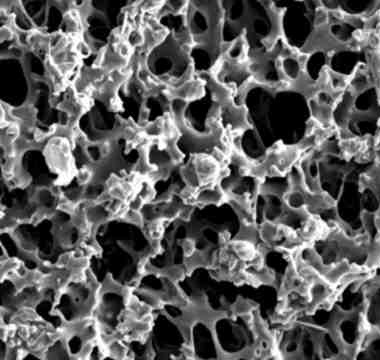

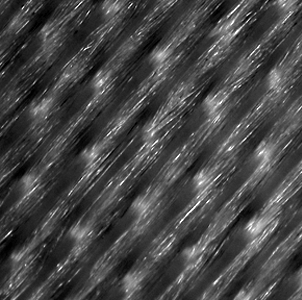

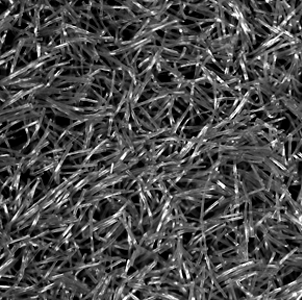

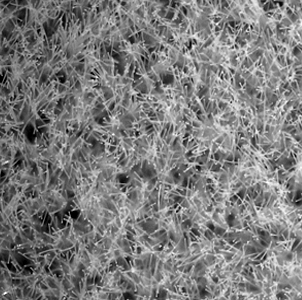

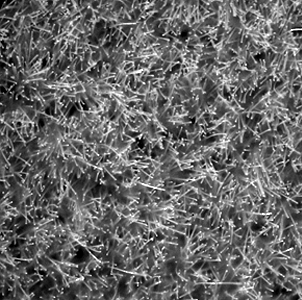

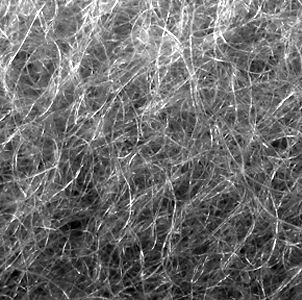

PACE Technologies' polycrystalline diamond polishing abrasives are designed for rapid material removal with minimal surface damage. Featuring a multi-faceted crystal structure, these abrasives enhance surface leveling and reduce sub-surface deformation, making them ideal for polishing hard and brittle materials. Compatible with a wide range of polishing cloths and lubricants, polycrystalline diamond provides superior performance in both intermediate and final polishing stages.

Key Tips for Diamond Polishing

- Select Appropriate Viscosity: Use high-viscosity suspensions for aggressive polishing, and low-viscosity for delicate or heat-sensitive materials.

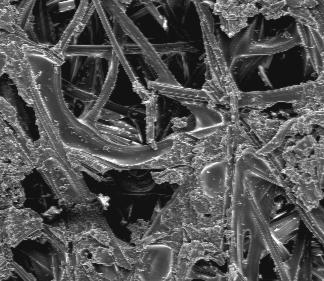

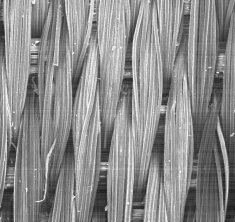

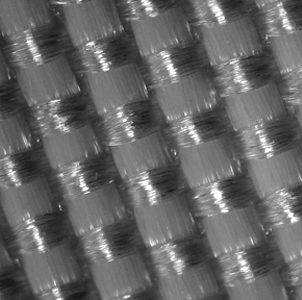

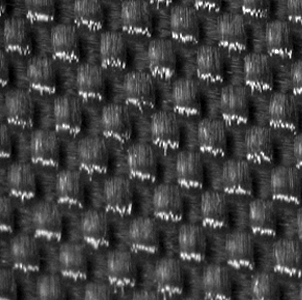

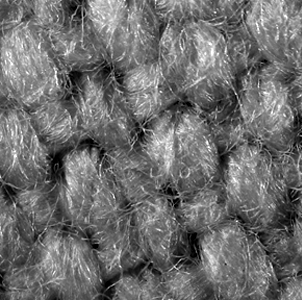

- Pair with Compatible Pads: Use low-nap or non-woven polishing pads to optimize abrasive contact and surface finish.

- Adjust Force and Time: Polycrystalline diamond cuts faster, so reduce polishing time and pressure to prevent over-polishing or relief.

- Clean Between Steps: Prevent cross-contamination by thoroughly cleaning specimens, pads, and platens between polishing stages.

View in our shop:

For Monocrystalline Diamond Polishing

More Resources:

Introduction

Polycrystalline diamond polishing is a critical step in achieving uniform, high-quality surface finishes during metallographic sample preparation. With its multi-faceted crystal structure, polycrystalline diamond offers superior material removal rates and minimized subsurface damage, especially on hard and brittle materials. These abrasives are best used with low- to medium-napped polishing pads to maintain flatness and avoid issues like relief or edge rounding. Selecting the proper viscosity and suspension format—paired with the right cloth and lubrication—ensures efficient, reproducible polishing results for accurate microstructural analysis.

Diamond Abrasive Selection Guidelines

This reference outlines best-practice abrasive sizes for rough and final polishing across metals, ceramics, and composite materials. Proper abrasive selection is critical to ensure accurate microstructural representation, prevent surface damage, and optimize polishing efficiency.

Polishing Guide for Metals

| Metal | Rough Polishing (Diamond) | Final Polishing (Oxide) | ||||

|---|---|---|---|---|---|---|

| Abrasive Size | 9 µm | 6 µm | 3 µm | 1 µm | Al2O3 | SiO2 |

| Aluminum | ||||||

| Copper / Brass | ||||||

| Stainless Steel | ||||||

| Soft Steel | ||||||

| Hard Steel | ||||||

| Tool Steel | ||||||

| Titanium | Etch Polish | |||||

| Zinc, Tin, Lead | ||||||

Polishing Guide for Ceramics and Composites

| Ceramic / Composite | Coarse Grind | Fine Grind | Rough Polish | Fine Polish | ||

|---|---|---|---|---|---|---|

| Diamond Size | 30 µm | 15 µm | 9 µm | 6 µm | 3 µm | 1 µm + SiO2 |

| Alumina | ||||||

| Silicon Nitride | ||||||

| Polymer Composite | ||||||

| Metal Matrix Composite | ||||||

| Ceramic Matrix Composite | ||||||

| Cermet | ||||||

Note: These selections reflect proven laboratory procedures balancing speed, flatness, and structure preservation. Adjust abrasive types and sequence for material-specific variables such as grain size, hardness, and thermal sensitivity.

Polishing Pad Selection Guideline

Process Description

Polycrystalline diamond polishing is typically performed in one or two stages depending on material hardness and surface condition. For rough polishing, low- to medium-napped pads are used with coarse polycrystalline diamond suspensions or pastes to efficiently remove grinding damage. In many cases, this may be followed by a finer grade of polycrystalline diamond for surface refinement. Due to the abrasive’s multi-crystalline nature, material removal is rapid yet controlled, minimizing heat and deformation. Excessive polishing should be avoided to prevent artifacts such as relief, smear, or rounding.

Minimizing Polishing Artifacts

To prevent common polishing issues such as edge rounding, relief, or abrasive embedding:

- Use polycrystalline diamond suspensions with the correct viscosity for your application

- Select low-napped pads to maintain surface flatness during rough polishing

- Ensure polishing plates have minimal runout (≤2.5 µm for 8" platens)

- Use moderate force and avoid prolonged polishing times

Recommended Procedures

- Secure the polishing pad firmly to a flat platen (adhesive or magnetic backing as appropriate)

- Pre-wet and pre-charge the pad with polycrystalline diamond suspension or paste

- Apply the recommended lubricant to optimize cutting and prevent pad clogging

- Start polishing with reduced downforce to avoid premature pad wear or sample relief

- Rinse specimen and pad with water or ethanol during the final 10–15 seconds of polishing

- Clean and dry specimens thoroughly to remove all residues before inspection

Troubleshooting

| Symptom | Cause | Solution |

|---|---|---|

| Coarse Scratching | Contaminated polishing pad or incorrect pad pairing | Replace pad; use correct pad type for polycrystalline diamond |

| Agglomerated Diamond | Pre-mixing with colloidal silica; bacterial growth in suspension | Dispense abrasives separately; replace suspension if contaminated |

| Uneven Polishing | Worn pad or uneven platen surface | Replace pad; check and resurface platen if needed |

| Edge Rounding / Excessive Relief | Too much downforce or extended polishing duration | Reduce force; shorten polishing time; verify prior steps were sufficient |

| Low Polishing Rate | Insufficient abrasive concentration or poor pad saturation | Increase suspension application rate; recharge pad with diamond |

| Tearing of Pad | High pressure or inadequate lubrication | Lower pressure; apply lubricant more frequently |

| Specimen Smear or Pull-Out | Inappropriate pad or overly aggressive abrasive size | Use lower nap pad and finer diamond grit; evaluate pad compatibility |

Polycrystalline Diamond Suspensions (water-based)

Polycrystalline Diamond Suspension – Dyed

| Description | Quantity | Catalog Number | Product Image |

|---|---|---|---|

| 1 micron (blue) DIAMAT PC Suspension | 1 liter | PC-1001-1L |  |

| 1 micron (blue) DIAMAT PC Suspension | 1 gallon | PC-1001-1GLB | |

| 3 micron (green) DIAMAT PC Suspension | 1 liter | PC-1003-1L |  |

| 3 micron (green) DIAMAT PC Suspension | 1 gallon | PC-1003-1GLG | |

| 6 micron (yellow) DIAMAT PC Suspension | 1 liter | PC-1006-1L |  |

| 6 micron (yellow) DIAMAT PC Suspension | 1 gallon | PC-1006-1GLY | |

| 9 micron (red) DIAMAT PC Suspension | 1 liter | PC-1009-1L |  |

| 9 micron (red) DIAMAT PC Suspension | 1 gallon | PC-1009-1GLR | |

| 15 micron (brown) DIAMAT PC Suspension | 1 liter | PC-1015-1L |  |

| 15 micron (brown) DIAMAT PC Suspension | 1 gallon | PC-1015-1GLBR | |

| 30 micron (orange) DIAMAT PC Suspension | 1 liter | PC-1030-1L |  |

| 30 micron (orange) DIAMAT PC Suspension | 1 gallon | PC-1030-1GLO | |

| 45 micron (purple) DIAMAT PC Suspension | 1 liter | PC-1045-1L |  |

| 45 micron (purple) DIAMAT PC Suspension | 1 gallon | PC-1045-1GLP |

Polycrystalline Diamond Paste

| Description | Quantity | Catalog Number | Product Image |

|---|---|---|---|

| DIAMAT Polycrystalline Diamond Paste (0.1 µm) | 5 gm 20 gm |

PC-0210-05 PC-0210-20 |

|

| DIAMAT Polycrystalline Diamond Paste (0.25 µm) | 5 gm 20 gm |

PC-0225-05 PC-0225-20 |

|

| DIAMAT Polycrystalline Diamond Paste (0.5 µm) | 5 gm 20 gm |

PC-0250-05 PC-0250-20 |

|

| DIAMAT Polycrystalline Diamond Paste (1 µm) | 5 gm 20 gm |

PC-2001-05 PC-2001-20 |

|

| DIAMAT Polycrystalline Diamond Paste (3 µm) | 5 gm 20 gm |

PC-2003-05 PC-2003-20 |

|

| DIAMAT Polycrystalline Diamond Paste (6 µm) | 5 gm 20 gm |

PC-2006-05 PC-2006-20 |

|

| DIAMAT Polycrystalline Diamond Paste (9 µm) | 5 gm 20 gm |

PC-2009-05 PC-2009-20 |

|

| DIAMAT Polycrystalline Diamond Paste (15 µm) | 5 gm 20 gm |

PC-2015-05 PC-2015-20 |

|

| DIAMAT Polycrystalline Diamond Paste (30 µm) | 5 gm 20 gm |

PC-2030-05 PC-2030-20 |

|

| DIAMAT Polycrystalline Diamond Paste (45 µm) | 5 gm 20 gm |

PC-2045-05 PC-2045-20 |

|