Monocrystalline Diamond Polishing

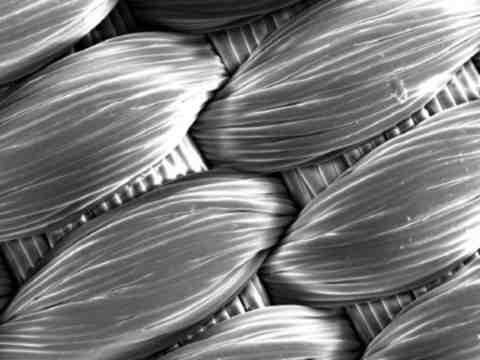

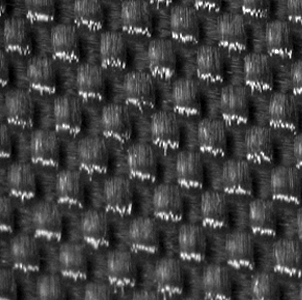

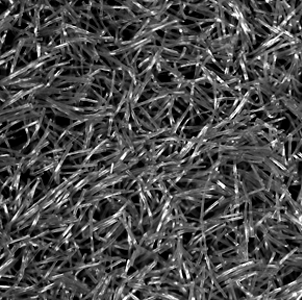

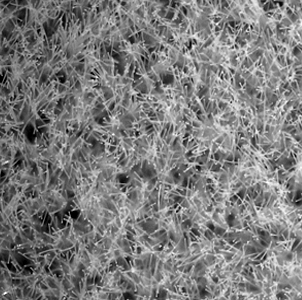

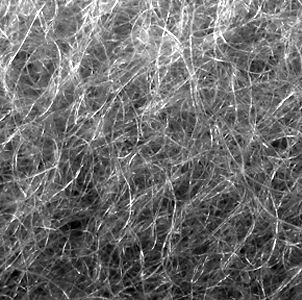

PACE Technologies' monocrystalline diamond polishing abrasives deliver sharp, angular cutting action for high-efficiency material removal in metallographic sample preparation. These single-crystal abrasives are best suited for applications requiring aggressive polishing and long abrasive life. Ideal for metals and alloys, monocrystalline diamond supports a consistent, repeatable polishing process that minimizes polishing times and enhances throughput in quality control and research environments.

Key Tips for Monocrystalline Diamond Polishing

- Choose the Right Viscosity: High-viscosity for rapid removal; low-viscosity for fine control or sensitive samples.

- Use Compatible Pads: Pair with low-nap or resilient pads for optimal flatness and abrasive efficiency.

- Control Force and Duration: Monocrystalline diamond is aggressive—use moderate pressure and shorter cycles.

- Clean Thoroughly: Rinse specimens and equipment between steps to avoid abrasive carryover.

View in our shop:

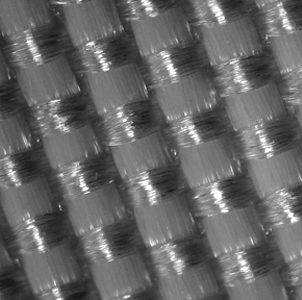

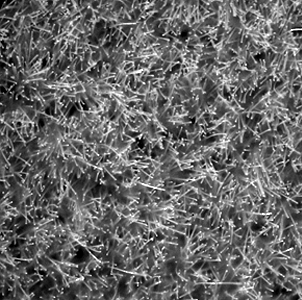

For Polycrystalline Diamond Polishing

More Resources:

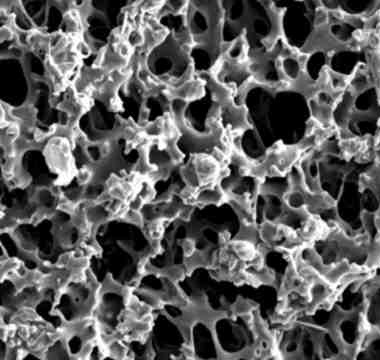

Introduction

Monocrystalline diamond polishing plays a vital role in producing sharp, high-resolution surface finishes in metallographic sample preparation. Composed of single-crystal diamond particles, these abrasives exhibit angular, blocky shapes that deliver fast, aggressive cutting action—ideal for metals and harder materials. Monocrystalline diamond is best used with resilient, low- to medium-napped polishing pads to maintain planarity and minimize smearing. Proper selection of abrasive size, suspension medium, and compatible lubrication ensures precise, efficient polishing with consistent material removal and excellent edge retention.

Diamond Abrasive Selection Guidelines

This reference outlines best-practice abrasive sizes for rough and final polishing across metals, ceramics, and composite materials. Proper abrasive selection is critical to ensure accurate microstructural representation, prevent surface damage, and optimize polishing efficiency.

Polishing Guide for Metals

| Metal | Rough Polishing (Diamond) | Final Polishing (Oxide) | ||||

|---|---|---|---|---|---|---|

| Abrasive Size | 9 µm | 6 µm | 3 µm | 1 µm | Al2O3 | SiO2 |

| Aluminum | ||||||

| Copper / Brass | ||||||

| Stainless Steel | ||||||

| Soft Steel | ||||||

| Hard Steel | ||||||

| Tool Steel | ||||||

| Titanium | Etch Polish | |||||

| Zinc, Tin, Lead | ||||||

Polishing Guide for Ceramics and Composites

| Ceramic / Composite | Coarse Grind | Fine Grind | Rough Polish | Fine Polish | ||

|---|---|---|---|---|---|---|

| Diamond Size | 30 µm | 15 µm | 9 µm | 6 µm | 3 µm | 1 µm + SiO2 |

| Alumina | ||||||

| Silicon Nitride | ||||||

| Polymer Composite | ||||||

| Metal Matrix Composite | ||||||

| Ceramic Matrix Composite | ||||||

| Cermet | ||||||

Note: These selections reflect proven laboratory procedures balancing speed, flatness, and structure preservation. Adjust abrasive types and sequence for material-specific variables such as grain size, hardness, and thermal sensitivity.

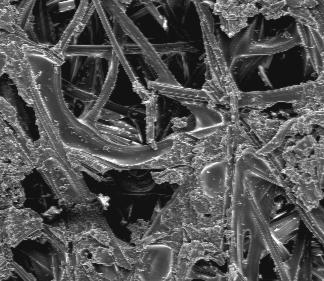

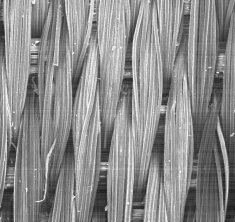

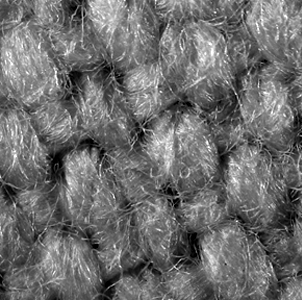

Polishing Pad Selection Guideline

Process Description

Monocrystalline diamond polishing is commonly used in one or more stages to remove grinding damage and achieve smooth, reflective surfaces on metals and hard materials. The sharp, angular particles of monocrystalline diamond provide aggressive cutting, making it ideal for high-efficiency rough and intermediate polishing. Use coarser grades for initial steps, followed by finer grades to refine the surface. To avoid surface damage, polishing time and pressure should be carefully controlled.

Minimizing Polishing Artifacts

To reduce edge rounding, relief, and embedding during monocrystalline diamond polishing:

- Choose the correct abrasive size and viscosity for the material and stage

- Use low-nap or non-woven pads to support flat, uniform surfaces

- Ensure platens are flat and runout is under 2.5 µm (for 8" discs)

- Apply even pressure and limit polishing durations to avoid over-polishing

Recommended Procedures

- Secure the polishing pad firmly onto a flat, clean platen

- Apply several beads of monocrystalline diamond suspension or extender to initiate pad wetting — avoid full saturation

- Dispense additional diamond at a rate of 1–2 drops every 10–15 seconds during polishing, depending on speed and sample area

- Introduce a compatible lubricant to reduce heat and optimize abrasive performance

- For ceramic and mineral specimens, alternate diamond and colloidal silica (e.g., SIAMAT) for enhanced chemomechanical polishing (CMP)

- Begin polishing with moderate force to leverage the sharp, angular cutting action of monocrystalline diamond

- During the final 15 seconds of the cycle, flush the pad and specimen with water to remove residue and condition the surface

- After polishing, rinse specimens thoroughly and dry completely before microscopic inspection

Troubleshooting

| Symptom | Cause | Solution |

|---|---|---|

| Coarse Scratching | Old or contaminated suspension; excessive abrasive pressure | Use fresh monocrystalline suspension; reduce applied force |

| Uneven Material Removal | Poor abrasive distribution or inconsistent pad contact | Ensure even application of suspension; verify flat, stable platen setup |

| Pad Glazing | Diamond buildup or insufficient flushing | Flush regularly with water or alcohol; condition or replace pad |

| Edge Rounding | Over-polishing or inappropriate pad compliance | Reduce polishing time; use a firmer pad to maintain edge definition |

| Low Material Removal Rate | Low abrasive loading or degraded diamond suspension | Reapply suspension more frequently; check expiration of abrasive |

| Specimen Drag or Pad Tearing | Insufficient lubrication with high downforce | Increase lubricant volume; reduce pressure |

| Surface Smearing or Pull-Out | Overly aggressive grit size for specimen material | Switch to finer monocrystalline grit; ensure pad matches application |