Metallographic Abrasive Grinding Information

Introduction

The purpose of the grinding step is to remove damage from cutting, planarize the specimen(s), and to remove material approaching the area of interest. It is important to note that it is possible to create more damage in grinding than in sectioning. In other words, it is better to cut as close as possible to the area of interest using the correct abrasive or wafering blade.

The typical abrasives used for grinding include:

-Silicon Carbide (SiC)

-Alumina (ALO)

-Diamond

-Zirconia

Metallographic Abrasive Machining

The following are the most common metallographic abrasives:

Silicon Carbide

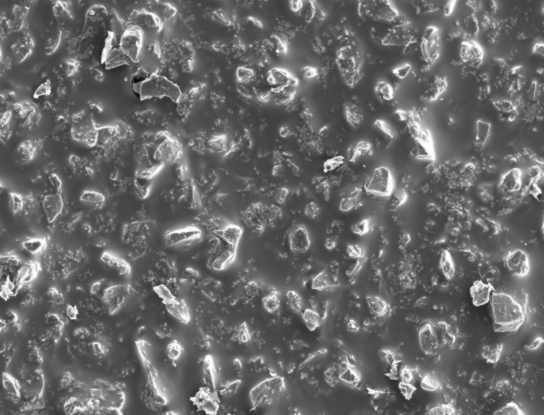

SiC is a manufactured abrasive produced by a high temperature reaction between silica and carbon. It has a hexagonal-rhombohedral crystal structure and has a hardness of approximately 2500 HV. It is an ideal abrasive for cutting and grinding because of its hardness and sharp edges. It is also somewhat brittle, and therefore it cleaves easily to produce sharp new edges (self sharpening). SiC is an excellent abrasive for maximizing cutting rates while minimizing surface and subsurface damage. For metallographic preparation, SiC abrasives are used in abrasive blades and for coated abrasive grinding papers ranging from very coarse 60 grit to very fine 1200 grit sizes.

Bonded or coated abrasive papers of SiC are designed so that the abrasive will have a large number of cutting points (negative abrasive rank angle). This is achieved by aligning the abrasive particles approximately normal to the backing. Note that coated abrasives are not quite coplanar, thus SiC papers produce the maximum efficiency (cut rate, stock removal and minimal damage) because new abrasive is exposed as the old abrasive breaks down.

SEM micrograph of 600 grit SiC Abrasive Paper (original mag. 150x)

Alumina

Alumina is a naturally occurring material (Bauxite). It exits in either the softer gamma (mohs 8) or harder alpha (mohs 9, 2000 HV) phase. Alumina abrasives are used primarily as a final polishing abrasive because of their high hardness and durability. Unlike SiC, alumina breaks down relatively easily to submicron or colloidal particles.

Note that larger coated or bonded grit sizes of alumina are commercially available, however they are not ideal for metallographic applications because they become dull, resulting in lower cut rates and higher surface and subsurface damage.

Diamond

Is the hardest material known to man (mohs 10, 8000 HV). It has a cubic crystal structure, and is available as a natural or an artificial product. Although diamond would be ideal for coarse grinding, its price makes it a very inefficient grinding material for anything except for hard ceramics. For metallographic applications, polycrystalline diamond is recommended as a rough polishing abrasive.

Zirconia

Zircon, or zirconium silicate, is another less common abrasive used for coarse grinding. It is a very tough abrasive, so it lasts longer, however it is generally not as hard or sharp, and thus requires higher pressures to be effective. Typically 60 or 120 grit sizes have been found to be the most useful grain sizes for metallographic grinding with zircon.

For metallographic abrasives the particle size is typically classified by grit size or average particle size in microns. Grit size would refer to the size of the particle if it were classified or sized with mesh screens. Roughly speaking, grit size represents the number of wires or mesh of wires per a specified area. Thus larger grits numbers would represent smaller or more openings in a mesh screen and thus would correlate to smaller sized particles. For example, a 120 grit particle is approxmiately 105 microns in size, whereas, a 1200 grit particle has a particle size of 2.5 microns. The difference between the European P-grading system (number has a P in front of the number) and the more common ANSI or CAMI standard is that the European number is based on the number of openings if the width of the wire mesh was eliminated from the calculation. Therefore for larger particles the P-grading is approximately the same as the ANSI or CAMI number (e.g. 120 grit = P120 grit), whereas, for finer particles the P-grading number can be much larger (e.g. 1200 grit = P4000 grit)

(P-grade)

Grinding Parameters

Successful grinding is also a function of the following parameters:

Abrasive Grinding Selection Guidelines Charts

| Material | Objective | Recommendation |

|---|---|---|

| Soft non-ferrous metals (aluminum, copper, brass, tin, zinc, lead, etc.) | Minimize abrasive embedding and deformation on the surface | P120 grit ALO paper

P220 grit ALO paper P500 grit ALO paper P1200 grit ALO paper |

| Soft ferrous metals (low carbon steels, stainless steel, case hardened steel, etc.) | Minimize deformation and secondary phase damage | 240 grit SiC paper

320 grit SiC paper 400 grit SiC paper 600 grit SiC paper 800 grit SiC paper 1200 grit SiC paper |

| Hard ferrous metals (high carbon steel, tool steel, case hardened steel, etc.) | Planarize specimen and minimize specimen deformation | 180 grit SiC paper

240 grit SiC paper 320 grit SiC paper 400 grit SiC paper 600 grit SiC paper |

| Super alloys (high nickel and cobalt alloys, titanium alloys) | Minimize deformation | 70 micron diamond disk 9 micron SIRIUS composite disk 3 micron ORION composite disk |

| Ceramics, ceramic matrix composites, and minerals | Minimize surface and subsurface damage (fracturing and chipping) | 30 um polycrystalline diamond on a Metal Mesh cloth |

| Metal matrix composites, polymer matrix composites | Minimize composite fracturing and minimizing matrix deformation | 240 or 320 grit SiC paper |

- Soft non-ferrous metals - Initial grinding is recommended with 320 grit SiC abrasive paper followed by 400, 600, 800 and 1200 grit SiC paper. Because these materials are relatively soft they do not easily break down the SiC paper. Thus initial grinding with 320 grit is generally sufficient for minimizing initial deformation and yet maintaining adequate removal rates. For extremely soft materials such as tin, lead and zinc it is also recommended that the abrasive paper be lightly coated with a paraffin wax. The wax reduces the tendency of the SiC abrasive to embed into the soft specimen.

- Soft ferrous metals - are relatvely easy to grind with the depth of deformation being a major consideration. 240 grit SiC abrasives provide a good initial start with subsequent use of 320, 400, 600, 800 and 1200 grit SiC.

- Hard ferrous metals - require more aggressive abrasives to achieve adequate material removal. Thus coarse SiC abrasives (120 or 180 grit) are recommended for stock removal requirements. Once planarity and the area of interest are obtained a standard 240, 320, 400 and 600 grit series is recommended.

- Super alloys - are generally of moderate hardness but have extremely stable elevated temperature characteristics and corrosion resistance. The procedures for preparing super alloys is very similar to that for most non-ferrous metals.

- Ceramics - are extremely hard, corrosion resistant and brittle materials. They fracture producing both surface and subsurface damage. Proper grinding minimizes both of these forms of damage. This requires the application of a semi-fixed abrasive which are held rigidly for grinding but can be dislodged under high stress in order to minimize subsurface damage. The use of a metal mesh cloth (CERMESH cloth) with an applied abrasive accomplishes both of these goals. The abrasive size is also important because very coarse abrasives will remove material quickly but can seriously damage the specimen. For ceramics, consideration of the damage produced at each preparation step is critical to minimizing the overall preparation sequence.

- Composites - are perhaps the most difficult specimens to prepare because of the wide range of properties for the materials used. For example, a metal matrix composite (MMC) such as silicon carbide ceramic particles in an aluminum metal matrix is a difficult specimen to prepare. This composite contains extremely hard/brittle ceramic particles dispersed in a relatively soft/ductile metal matrix. As a rule of thumb, initial grinding should focus on metal planarization and grinding to the area of interest. The secondary grinding steps require focusing on the ceramic particles and typically requires the use of diamond abrasives.

Abrasive Grinding Process Description

The machine parameters which affect the preparation of metallographic specimens include: grinding/polishing pressure, relative velocity distribution, and the direction of grinding/polishing.

Grinding Pressure

Grinding/polishing pressure is dependent upon the applied force (pounds or Newtons) and the area of the specimen and mounting material. Pressure is defined as the Force/Area (psi, N/m2 or Pa). For specimens significantly harder than the mounting compound, pressure is better defined as the force divided by the specimen surface area. Thus, for larger hard specimens higher grinding/polishing pressures increase stock removal rates, however higher pressure also increases the amount of surface and subsurface damage. Note for SiC grinding papers, as the abrasive grains dull and cut rates decrease, increasing grinding pressures can extend the life of the SiC paper.

Higher grinding/polishing pressures can also generate additional frictional heat which may actually be beneficial for the chemical mechanical polishing (CMP) of ceramics, minerals and composites. Likewise for extremely friable specimens such as nodular cast iron, higher pressures and lower relative velocity distributions can aid in retaining inclusions and secondary phases.

Relative Velocity

Current grinding/polishing machines are designed with the specimens mounted in a disk holder and machined on a disk platen surface. This disk on disk rotation allows for a variable velocity distribution depending upon the head speed relative to the base speed.

NOTE: Matching the head and base speed, while running in the same direction produces better flatness and lower surface damage because this minimizes the velocity distribution across the sample as it rotates.

|

|

| High relative velocity distribution for non-matching head and base speeds. | Constant relative velocity distribution for-matching head and base speeds. |

| Head Speed (rpm) |

Base Speed (rpm) |

Relative Velocity Distribution |

Characteristic | Application |

|---|---|---|---|---|

| 150 | 300 to 600 | High |

-Aggressive stock removal

-Differential grinding across the specimen surface |

-Useful for gross removal on hard specimens |

| 200 | 200 | Minimal |

-Matching head and base speed in the same direction eliminates relative velocity distributions -Uniform stock removal -Low stock removal -Produces minimal damage |

-Provides superior flatness over the specimen -Useful for retaining inclusions and brittle phases |

For high stock removal, a slower head speed relative to a higher base speed produces the most aggressive grinding/ polishing operation. The drawback to high velocity distributions is that the abrasive (especially SiC papers) may not breakdown uniformly, this can result in non-uniform removal across the specimen surface. Another disadvantage is that the high velocity distributions can create substantially more specimen damage, especially in brittle phases. In all cases, it is not recommended to have the head rotating contra direction to the base because of the non-uniform removal and abrasive break-down which occurs.

Minimal relative velocity distributions can be obtained by rotating the head specimen disk at the same rpm and same direction as the base platen. This condition is best for retaining inclusions and brittle phases as well as for obtaining a uniform finish across the entire specimen. The disadvantage to low relative velocity distributions is that stock removal rates can be quite low.

In practice, the best condition to run the polishing machine is by matching the head and base speeds at 200 rpm and in the same direction. For polishing it is recommended that the speed be reduce to 100/100 rpm base/head speed. For final polishing under chemical mechanical polishing (CMP) conditions where frictional heat can enhance the chemical process, high speeds and high relative velocity distributions can be useful as long as brittle phases are not present (e.g. monolithic ceramics such as silicon nitride and alumina).

Grinding Direction

The orientation of the specimen can have a significant impact on the preparation results, especially for specimens with coatings. In general, when grinding and polishing materials with coatings the brittle component should be kept in compression. In other words, for brittle coatings the direction of the abrasive should be through the coating and into the substrate. Conversely, for brittle substrates with ductile coatings, the direction of the abrasive should be through the brittle substrate into the ductile coating.

Abrasive Grinding Recommend Procedures Application

(Fixed-abrasive Grinding)

- Start with the finest abrasive possible (typically 240 or 320 grit abrasive paper) Note: Only use coarser grit for very heavy stock removal

- Apply lubricant to abrasive surface

- Most commonly water

- Water soluble oils for water sensitive specimens

- Rinse specimens thoroughly before proceeding to the next finer abrasive

- Apply CERMESH metal mesh cloth to flat base surface (Suggestion - peel back protective paper at one corner and align and place on base surface. Pull protective paper with one hand while guiding metal mesh cloth with other hand)

- Pre-charge CERMESH metal mesh cloth with DIAMAT polycrystalline diamond

- To avoid tearing the cloth, begin initial grinding at 50% force to set specimen(s) to metal mesh cloth

- Ramp-up force gradually

- Add abrasive as required

- Rinse CERMESH metal mesh cloth with water at the end of the grinding cycle to remove swarf debris

Grinding Surface Backing

Grinding papers come with different types of backing

- Plain-backed or non-adhesive backing

- PSA or pressure sensitive backing

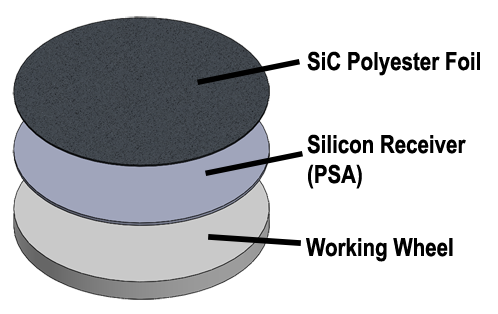

- Foil or polyester plastic backing

Plain-backed papers are the least expensive, however, they require either a double sided adhesive or a paper holding ring. The disadvanatage to using a paper holiding ring is that the mounted specimen cannot track over the edge of the grinding paper. Thus the paper does not break down uniformly and thus can produce over grinding of the mount away from the sample. This artifact results in the polished mount exhibiting a crescent moon which can affect the edge of the speciment. This artifact has also been known as "mooning" or MRD (material removal differential).

PSA-backed of adhesive backed papers are removal grinding papers. They are more expensive than the plain-backed papers and the foil papers. They are very easy to use and avoid the problems with "mooning" and MRD if the sample tracks over both the center and edge of the grinding papers.

Foil-backed or polyester backed grinding papers are easy to use and are more economical than adhesive backed papers. The system uses a receiver adhesive disk that can be washed in order to extend their lifes.

|

|

Abrasive Grinding Trouble Shooting

| Symptom | Cause | Action |

|---|---|---|

| Uneven grinding across the specimen and mount |

-Improper tracking of specimen over abrasive paper -Unequal head / base speeds |

-Orient specimen in holder so that the hardest portion of the specimen/mount tracks over the entire abrasive paper (uniform degradation of paper) -Match the head and base speed and rotate in the same direction. -Grinding at 200/200 rpm and polishing at 100/100 rpm |

Excessive vibration in machine |

-Too high a load or too low a speed -Inadequate machine design -Improper lubricant -Unequal head / base speeds |

-Reduce initial grinding force or increase grinding speed -Check with equipment vendor for equipment upgrades -Increase lubricant flow and/or use a water-soluble lubricant -Match the head and base speed and rotate in the same direction. - Grinding at 200/200 rpm and polishing at 100/100 rpm |

| Embedding of fractured abrasive grains |

-Common in the grinding of very soft materials -Unequal head / base speeds |

-Use alumina grinding papers vs. SiC papers |

<a href="https://www.metallographic.com/Metallographic-Consumables/Metallography-SiC-Papers.htm">

<a href="https://www.metallographic.com/Metallographic-Consumables/Metallography-SiC-Papers.htm">SiC Abrasive Paper (w/PSA)

SiC Abrasive Paper (PSA-pressure sensative adhesive) - 100/pkg

| Description | 8-inch Diameter |

10-inch Diameter |

12-inch Diameter |

14-inch Diameter |

|---|---|---|---|---|

| 60 grit SiC paper w/ PSA adhesive | SIC-060P8-100 | SIC-060P10-100 | SIC-060P12-100 | SIC-060P14-100 |

| 80 grit SiC paper w/ PSA adhesive | SIC-080P8-100 | SIC-080P10-100 | SIC-080P12-100 | SIC-080P14-100 |

| 120 grit SiC paper w/ PSA adhesive | SIC-120P8-100 | SIC-120P10-100 | SIC-120P12-100 | SIC-120P14-100 |

| 180 grit SiC paper w/ PSA adhesive | SIC-180P8-100 | SIC-180P10-100 | SIC-180P12-100 | SIC-180P14-100 |

| 240 grit SiC paper w/ PSA adhesive | SIC-240P8-100 | SIC-240P10-100 | SIC-240P12-100 | SIC-240P14-100 |

| 320 grit SiC paper w/ PSA adhesive | SIC-320P8-100 | SIC-320P10-100 | SIC-320P12-100 | SIC-320P14-100 |

| 360 grit SiC paper w/ PSA adhesive | SIC-360P8-100 | SIC-360P10-100 | SIC-360P12-100 | SIC-360P14-100 |

| 400 grit SiC paper w/ PSA adhesive | SIC-400P8-100 | SIC-400P10-100 | SIC-400P12-100 | SIC-400P14-100 |

| 600 grit SiC paper w/ PSA adhesive | SIC-600P8-100 | SIC-600P10-100 | SIC-600P12-100 | SIC-600P14-100 |

| 800 grit SiC paper w/ PSA adhesive | SIC-800P8-100 | SIC-800P10-100 | SIC-800P12-100 | SIC-800P14-100 |

| 1000 grit SiC paper w/ PSA adhesive | SIC-1000P8-100 | SIC-1000P10-100 | SIC-1000P12-100 | SIC-1000P14-100 |

| 1200 grit SiC paper w/ PSA adhesive | SIC-1200P8-100 | SIC-1200P10-100 | SIC-1200P12-100 | SIC-1200P14-100 |

Alumina Abrasive Paper (w/PSA)

ALO Abrasive Paper (PSA-pressure sensative adhesive) - 100/pkg

| Description | 8-inch Diameter |

10-inch Diameter |

12-inch Diameter |

|---|---|---|---|

| P120-grit Alumina (PSA-backed) | ALO-120P8-100 | ALO-120P10-100 | ALO-120P12-100 |

| P220-grit Alumina (PSA-backed) | ALO-220P8-100 | ALO-220P10-100 | ALO-220P12-100 |

| P500-grit Alumina (PSA-backed) | ALO-500P8-100 | ALO-500P10-100 | ALO-500P12-100 |

| P1200-grit Alumina (PSA-backed) | ALO-1200P8-100 | ALO-1200P10-100 | ALO-1200P12-100 |

SiC Abrasive Paper (Plain backed)

SiC ABRASIVE PAPER (Plain Backed)

| Description | 8-inch Diameter |

10-inch Diameter |

12-inch Diameter |

14-inch Diameter |

|---|---|---|---|---|

| 60 grit SiC paper plain backed | SIC-2108-060 | SIC-2110-060 | SIC-2112-060 | SIC-2114-060 |

| 80 grit SiC paper plain backed | SIC-2108-080 | SIC-2110-080 | SIC-2112-080 | SIC-2114-080 |

| 120 grit SiC paper plain backed | SIC-2108-120 | SIC-2110-120 | SIC-2112-120 | SIC-2114-120 |

| 180 grit SiC paper plain backed | SIC-2108-180 | SIC-2110-180 | SIC-2112-180 | SIC-2114-180 |

| 240 grit SiC paper plain backed | SIC-2108-240 | SIC-2110-240 | SIC-2112-240 | SIC-2114-240 |

| 320 grit SiC paper plain backed | SIC-2108-320 | SIC-2110-320 | SIC-2112-320 | SIC-2114-320 |

| 360 grit SiC paper plain backed | SIC-2108-360 | SIC-2110-360 | SIC-2112-360 | SIC-2114-360 |

| 400 grit SiC paper plain backed | SIC-2108-400 | SIC-2110-400 | SIC-2112-400 | SIC-2114-400 |

| 600 grit SiC paper plain backed | SIC-2108-600 | SIC-2110-600 | SIC-2112-600 | SIC-2114-600 |

| 800 grit SiC paper plain backed | SIC-2108-800 | SIC-2110-800 | SIC-2112-800 | SIC-2114-800 |

| 1200 grit SiC paper plain backed | SIC-2108-1200 | SIC-2110-1200 | SIC-2112-1200 | SIC-2114-1200 |

Alumina Abrasive Paper (plain backed)

ALO Abrasive Paper (Plain backed) - 100/pkg

| Description | 8-inch Diameter |

10-inch Diameter |

12-inch Diameter |

|---|---|---|---|

| P120-grit Alumina (Plain-backed) | ALO-2108-P120 | ALO-2110-P120 | ALO-2112-P120 |

| P120-grit Alumina (Plain-backed) | ALO-2108-P220 | ALO-2110-P220 | ALO-2112-P220 |

| P120-grit Alumina (Plain-backed) | ALO-2108-P500 | ALO-2110-P500 | ALO-2112-P500 |

| P120-grit Alumina (Plain-backed) | ALO-2108-P1200 | ALO-2110-P1200 | ALO-2112-P1200 |

Double Sided Adhesive (for non PSA paper)

| Description | Diameter (inches) | Quantity | Catalog Number |

|---|---|---|---|

| Double Sided Adhesive | 8 | 10/pkg | DSA-08 |

| Double Sided Adhesive | 10 | 10/pkg | DSA-10 |

| Double Sided Adhesive | 12 | 10/pkg | DSA-12 |

| Double Sided Adhesive | 14 | 10/pkg | DSA-14 |

Zirconia Abrasive Papers

Zirconia Coarse Grinding Disks

| Description | Units/pkg | Catalog Number |

|---|---|---|

| 8-inch 60 grit Zirconia paper (PSA) | 25/box | ZR-060P08-25 |

| 12-inch 60 grit Zirconia paper (PSA) | 25/box | ZR-060P12-25 |

Abrasive Belts (4-inch x 36-inch)

| Description | Units/pkg | Catalog Number |

|---|---|---|

| 60 grit Zirconia belt | 5/box | ZrO2-B060 |

| 120 grit Zirconia belt | 5/box | ZrO2-B120 |

| 120 grit Alumina belt | 5/box | ALO-B120 |

| 60 grit SiC belt | 10/box | SIC-B60 |

| 80 grit SiC belt | 10/box | SIC-B80 |

| 120 grit SiC belt | 10/box | SIC-B120 |

| 180 grit SiC belt | 10/box | SIC-B180 |

| 240 grit SiC belt | 10/box | SIC-B240 |

| 320 grit SiC belt | 10/box | SIC-B320 |

| 400 grit SiC belt | 10/box | SIC-B400 |

Abrasive Rolls (3-7/16" width, 60-feet length, 5/8" core)

| Description | Units/pkg | Catalog Number |

|---|---|---|

| 240 grit SiC roll | each | SIC-240R-60 |

| 320 grit SiC roll | each | SIC-320R-60 |

| 360 grit SiC roll | each | SIC-360R-60 |

| 400 grit SiC roll | each | SIC-400R-60 |

| 600 grit SiC roll | each | SIC-600R-60 |

| 800 grit SiC roll | each | SIC-800R-60 |

| 1200 grit SiC roll | each | SIC-1200R-60 |