Consumables Navigation

Metallographic Etchants (Technical)

COMMON ETCHANTS

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

Recommended Etchants

| Aluminum alloys | High carbon steel | |

|

|

|

| Brasses and Bronzes | Stainless steel | |

|

|

|

| Cast Iron | Tin alloys | |

|

|

|

| Copper alloys | Zinc alloys | |

|

|

|

| Welding or Low carbon steels | Ceramics | |

|

|

|

| Hastelloy and Nickel Superalloys | ||

|

The following table lists the most commonly used etchants offered by PACE Technologies

| Etchant | Composition | Conc. | Conditions | Comments |

|---|---|---|---|---|

| Adler Etchant | Copper ammonium chloride Hydrochloric acid Ferric chloride, hydrated DI Water |

9 grams 150 ml 45 grams 75 ml |

Immersion is recommended for several seconds | For etching 300 series stainless steel and other superalloys |

| Al-NaOH Etchant | NaOH Distilled water |

25 grams 250 ml |

Immersion is recommended for several seconds | For etching aluminum alloys |

| Ammonium Persulfate Etchant | (NH4)2S2O8 Distilled water |

50 grams 245 ml |

Immersion is recommended for several seconds | For brasses, especially brasses containing Cobalt |

| ASTM No. 30 | Ammonia Hydrogen Peroxide (3%) DI Water |

62.5 ml 125 ml 62.5 ml |

Mix Ammonia and water before adding peroxide. Must be used fresh. Swab 5-45 seconds | For etching copper, copper alloys and copper-silver alloys |

| ASTM 97 | KOH |

187.5 gram 245 ml |

Electrolytic at 2.5 V for few seconds | Fe-Cr-Ni alloys - Stains siga and chi yellow to red brown, ferrite gray to blue gray, carbides barely touched, austenite not touched |

| ASTM. No. 157 | CrO3 HCl Distilled water |

31.25 grams 187.54 ml 62.5 ml |

Immersion is recommended for several seconds | Hastelloy |

| Beraha's | Distilled water Na2S2O3 7.5 grams K2S2O5 |

250 ml 25 grams 7.5 grams |

Immersion is recommended for several seconds | For etching tool steel - Colors ferrite, martensite, bainite, and pearlite. Cementite unaffected |

| Carpenters Stainless Steel Etch | FeCl3 CuCl2 Hydrochloric acid Nitric acid Ethanol |

8.5 grams 2.4 grams 122 ml 6 ml 122 ml |

Immersion etching at 20 degrees Celsius | For etching duplex and 300 series stainless steels |

| Copper No.1 | Nitric acid Distilled water |

125 ml 125 ml |

Immersion etching at 20 degrees Celsius | Copper and brass Etchant |

| Copper No.2 | Distilled water HCl FeCl3 |

200 ml 50 ml 10 grams |

Immersion etching at 20 degrees Celsius | Copper and brass Etchant |

| CU-PASS-SOL | CuSO4-5H2O H2SO4 Distilled water |

40 grams 1.5 ml 245 ml |

This test is recommended for the detection of free iron on the surface of austenitic stainless steels in the 200 and 300 series, precipitation hardened stainless steels, and ferritic 400 series stainless steels having a minimum of 16 % chromium. A copper color on the metal surface (brown or pinkish) indicates that surface iron is still present and thus the part failures the test. If no reaction occurs it is considered a test pass | |

| Dichromate | H2SO4 Distilled water Ssaturated NaCl K2Cr2O7 |

36 ml 445 ml 18 ml 8.9 grams |

Cu-Sn (tin bronze) | |

| Fry's Etchant | HCl CuCl2, 75 ml d Distilled water Denatured alcohol |

100 ml 12.5 grams 75 ml 65 ml |

Fry's reagent for martensitic and precipitation hardenable grades of stainless steel | |

| Inconel Etchant | Solution A: |

50 ml 40 ml 75 ml 15 ml 35 ml 50 ml |

Do not STORE MIXED SOLUTIONS IN CLOSED CONTAINERS.Use Fresh and discard after mixing. | Macro etchant for Inconel-type alloys on NiCr and Ni-Fe-Cr basis. Etchant for Ni-Nb, Ni-Ta, Ni-Si, Ni-Co-Cr alloys |

| Kalling's No. 2 | CuCl2 Hydrochloric acid Ethanol |

5 grams 100 ml 100 ml |

Immersion or swabbing etch at 20 degrees Celsius | For etching duplex and 400 series stainless steels and Ni-Cu alloys and superalloys. |

| Kellers Etch | Distilled water Nitric acid Hydrochloric acid Hydrofluoric acid |

190 ml 5 ml 3 ml 2 ml |

10-30 second immersion. Use only fresh etchant | Excellent for aluminum and titanium alloys. |

| Klemm's Reagent | Sodium thiosulfate solution Potassium metabisulfite |

250 ml Saturated 5 grams |

Etch for a few seconds to minutes | For etching alpha-beta brass, bonze, tin, cast iron phosphides, ferrite, martensite, retained austenite, zinc and steel temper embrittlement. |

| Kroll’s Reagent | Distilled water Nitric acid Hydrofluoric acid |

92 ml 6 ml 2 ml |

Swab specimen up to 20 seconds |

Excellent for titanium and alloys. |

| Marble's Reagent | CuSO4 Hydrochloric acid Water |

10 grams 50 ml 50 ml |

Immerse or swab for 5-60 seconds. |

For etching Ni, Ni-Cu and Ni-Fe alloys and superalloys. Add a few drops of H2SO4 to increase activity. |

| Murakami's | K3Fe(CN)6 KOH Water |

10 grams 10 grams 100 ml |

Pre-mix KOH and water before adding K3Fe(CN)6 |

Cr and alloys (use fresh and immerse); iron and steels reveals carbides; Mo and alloys uses fresh and immerse; Ni-Cu alloys for alpha phases use at 75 Celcius; W and alloys use fresh and immerse; WC-Co and complex sintered carbides. |

| Nital | Ethanol Nitric acid |

100 ml 1-10 ml |

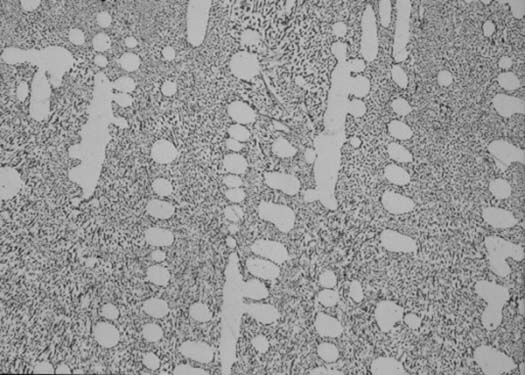

Immersion up to a few minutes. | Most common etchant for Fe, carbon and alloys steels and cast iron - Immerse sample up from seconds to minutes; Mn-Fe, MnNi, Mn-Cu, Mn-Co alloys. |

| Oberhoffers | Solution A: Ethanol, Distilled water FeCl3 SnCl2) Solution B: Distilled water HCl |

|

Use fresh | Steels and special steels. Fe-enriched areas appear dark |

| Picral | Ethanol Picric acid |

100 ml 2-4 grams |

Seconds to minutes Do not let etchant crystallize or dry –explosive |

Recommended for microstructures containing ferrite, carbide, pearlite, martensite and bainite. Also useful for magnetic alloys, cast iron, high alloy stainless steels and magnesium. |

| Ralphs etchant | Distilled water Methyl alcohol HCl CuCl2 FeCl3 |

62.5 ml 125 ml 62.5 ml 1.25 grams 4.4 grams |

Seconds to minutes | Ferritic stainless steels |

| TI-AP-16 | SiO2, 43 ml NH4OH, 16 ml 30% H2O2 |

432 ml 43 ml 16 ml |

Apply to polishing pad, rinse after use | Enhances the polishing rates and improves surface finishes for titanium alloys |

| V2A Etchant | HCl HNO3 Distilled water |

119 ml 19 ml 119 ml |

Immersion is recommended for several seconds | Austenitic stainless steel etchant |

| Vilella’s Reagent | Picric Acid Hydrochloric acid Ethanol |

1 gram 5 ml 100 ml |

Seconds to minutes | Good for ferrite-carbide structures (tempered martensite) in iron and steel |

| Waterless Kallings | CuCl2, 125 ml HCl, Denatured alcohol | 6.25 gm 125 ml |

Seconds to minutes | Waterless Kalling's reagent; for iron-base and nickel-base superalloys |

| Wecks | 7.5 grams ammonium bifluorides HCl Distilled water |

4.5 grams 10 ml 240 ml |

Seconds to minutes | Wecks tint etch for Ti and alloys. Alpha grains and twins colored according to orientation |

| Wecks No. 1 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

10 grams

2.5 grams 250 ml |

Seconds to minutes | Primarily used for aluminum and magnesium and their alloys to reveal grain boundaries, precipitates, and other microstructural features in aluminum alloys |

| Wecks No. 2 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

25 grams

25 grams 250 ml |

Seconds to minutes | Used for stainless steels, nickel-based alloys, and sometimes other metals to reveal grain boundaries, phases, and other microstructural features |

| Wecks No. 3 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

10 grams

25 grams 250 ml |

Seconds to minutes | Used for etching titanium alloys, stainless steels, and sometimes other resistant metals to reveal grain boundaries, phases, and other microstructural features, particularly in titanium alloys |

| Wecks No. 4 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

7.5 grams

25 grams 250 ml |

Seconds to minutes | Commonly used for etching aluminum alloys, magnesium alloys, and sometimes other light metals to reveal grain boundaries, phases, and other microstructural features in these metals |

| Wecks No. 5 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

5 grams

25 grams 250 ml |

Seconds to minutes | Typically used for less agressive etching magnesium alloys, aluminum alloys, and sometimes other light metals to reveal grain boundaries, phases, and other microstructural features in these metals |

| Wecks No. 5 | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

5 grams

25 grams 250 ml |

Seconds to minutes | Mildest Wecks reagent, often used for etching magnesium alloys, aluminum alloys, and other light metals to gently reveal grain boundaries, phases, and other microstructural features in these metals |

| Wecks Copper Reagent | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

12.5 grams

5 grams 250 ml |

Seconds to minutes | Effective for etching copper and copper alloys to reveal microstructure |

| Wecks Titanium Reagent | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

12.5 grams

5 grams 250 ml |

Seconds to minutes | Suitable for etching titanium alloys, allowing the observation of microstructural features such as grain boundaries and phase distribution |

| Wecks Zinc Reagent | Potassium Permanganate (KMnO₄)

Sodium Hydroxide (NaOH) Distilled water |

7.5 grams

2.5 grams 250 ml |

Seconds to minutes | Used for etching zinc and zinc-based alloys |

| Winsteards | Picric acid, 10 ml |

2 grams 10ml 200 ml 5 ml 5 drops |

Seconds to minutes | Low carbon steel - austentic grain boundaries |

| Current Selection The following information is generated automatically for display only. Tax may be changed. |

|---|

| Total value ($) | Choose Tax rate(%) | Sub total ($) |

|---|---|---|