|

|

|

Zinc-Aluminum Alloy

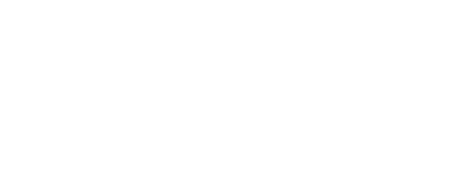

Specimen Preparation (Class 1 Procedures)

|

|

Zinc-aluminum alloys are difficult to prepare because they are soft and contain oxide particles which can become dislodged and scratch the surface. The key to polishing zinc-aluminum alloys is to use alumina polishing abrasives to reduce fractured abrasive particle embedding and to final polish with polycrystalline abrasives (fine aggregates).

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-C or MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Zinc-Aluminum Alloy, 200X B.F. (etchant CrO3, Na2SO4) |

|

| Zinc-Aluminum Alloy, 1000X DIC (etchant CrO3, Na2SO4) |

|

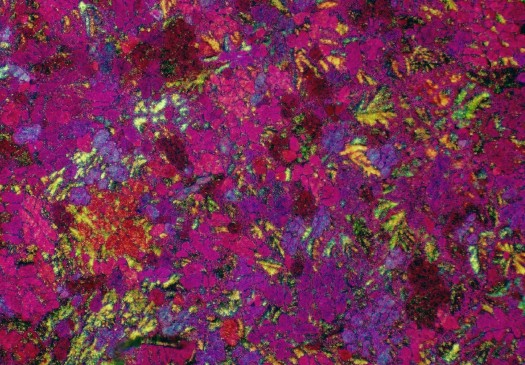

| Zinc-Aluminum Alloy, 100X Polarized (etchant CrO3, Na2SO4) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.