|

|

|

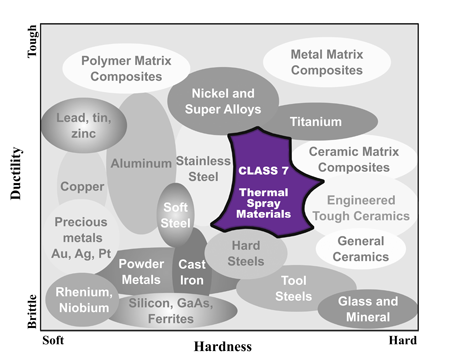

Superalloys with Ceramic Coating

Specimen Preparation (Class 7 Procedures)

|

|

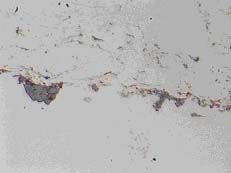

To improve both the wear and temperature resistance of Superalloys, coating of zirconia or other ceramics are applied to the turbine blade. Metallographic analysis is used to determine the quality and integrity of the coating, as well as, any delamination problems. In order to get an accurate measurement on the coating, specimen preparation must focus on minimizing damage to the coating. Minimizing damage as early as the abrasive cutting operation ensures successful preparation. For cutting ceramic coated Superalloys, the MAX-H series blade is recommended. Mounting with a fine EPOCOMP epoxy helps to better protect the surface during grinding and polishing.

Grinding must also minimize damage to the coating, so initial grinding should be with the finest SiC paper which provides acceptable grinding rates (e.g. 320 grit SiC paper). Final grinding down to 1200 grit SiC paper is recommended. For rough polish on a 3 micron diamond on a GOLDPAD polishing cloth produces a moderate finish that is flat across the various materials. For the final polish the use of our newly developed ATLANTIS polishing pad, which is a woven pad on a compressible foam backing produces excellent flatness and surface finishes. This pad, works extremely well for polishing materials of significantly different hardenss (i.e. metal substrate with ceramic coating). To also aid in the polishing of ceramic and metal combination materials, the use of colloidal silica as a lubricant / abrasive produces a chemical mechanical polishing effect (CMP) which provides the best finish and flatness for ceramic coating and metal interfaces.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-E or MAX-I series) (if required)

MOUNTING

Compression Mounting fine EPOCOMP Epoxy compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Zirconia thermal spray coating, as polished Mag 1000x (B.F.) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com