|

|

|

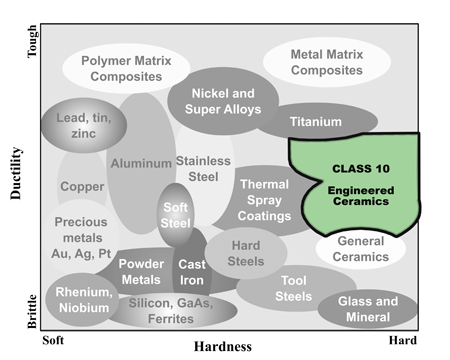

Silicon Nitride Engineering Ceramic

Specimen Preparation (Class 10 Procedures)

|

|

The key to proper specimen preparation of hard / tough ceramic materials such as silicon nitride (Si3N4) is to grind with a semi-fixed abrasive (polycrystalline diamond on a metal mesh cloth), followed by the use of CMP (chemical mechanical polishing) techniques using colloidal silica.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

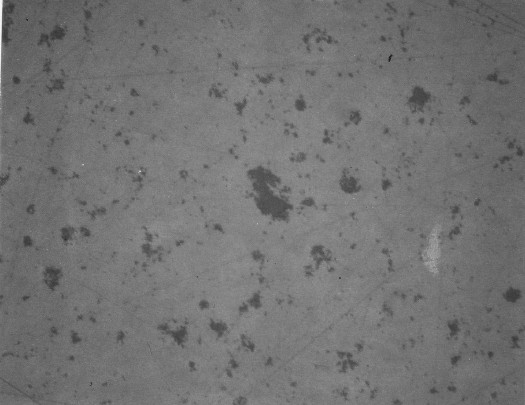

| Silicon Nitride polished with CMP techniques

400X (DIC) as polished |

|

| Silicon Nitride polished by conventional 9,6,3,1,0.25 um diamond steps. Note that the damage is not removed even after long polishing times. 400X (DIC) as polished |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com