|

|

|

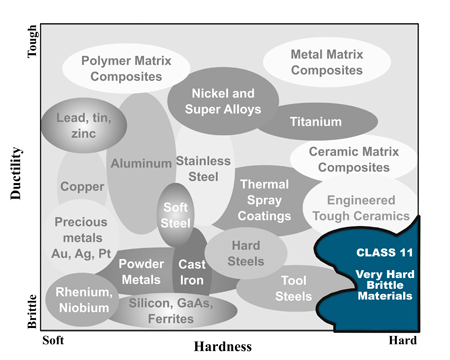

Periclase Mineral

Specimen Preparation (Class 11 Procedures)

|

|

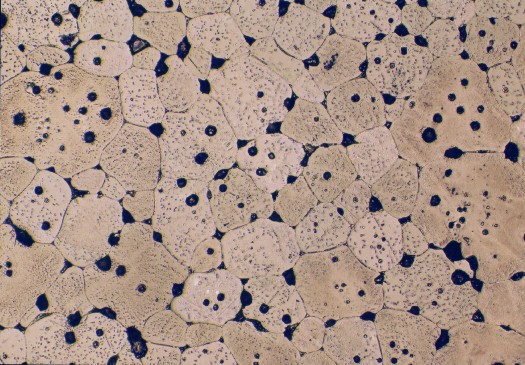

The microstructural preparation of hard minerals requires correctly cutting and initial grinding of the sample; followed by rough polishing and polishing which minimizes damage. The use of polycrystalline diamond on low napped polishing pads effectively reduces the damage to the specimen; which can easily be removed by final polishing with colloidal silica.

Proper microstructural preparation requires minimizing fracturing and damage during cutting and initial grinding. The use of colloidal silica as a CMP polishing lubricant and abrasive significantly improves the surface finish for this class of materials.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| Periclase, 200X (B.F.) Theraml etching at 1200 Celcius for 2 hours |

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com