|

|

|

Graphite Composite Specimen Preparation

(Class 1 Procedures)

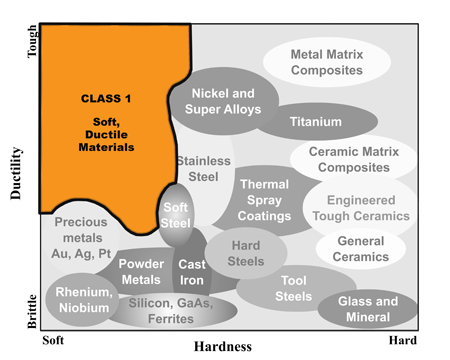

Proper preparation of polymer / graphite composites is required because the properties of the matrix material and the graphite particles vary significantly in both hardness and fracture toughness. As a general rule, the most difficult component to prepare in composite materials are the most brittle component (e.g. graphite particles). To properly polymer-graphite composites, initial sectioning must minimize damage. This is generally accomplished with a fine grit diamond wafering blade. Proceeding preparation steps must not add additional damage, this is accomplished by a matching the proper abrasive to to the proper polishing surface.

SECTIONING

Diamond Wafering blade - fine grit / low concentrationMOUNTING

Castable Mounting with Epoxy or Acrylic resinsPOLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

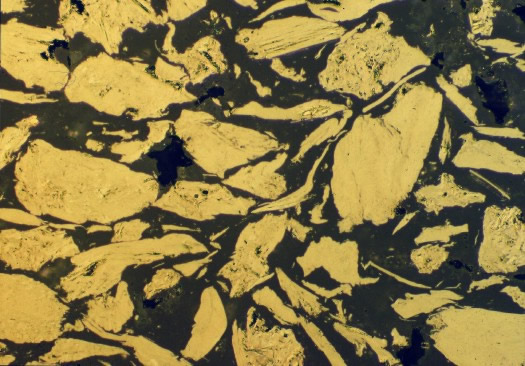

Polymer / Graphite Composite, as polished, 200X (B.F.) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com