|

|

|

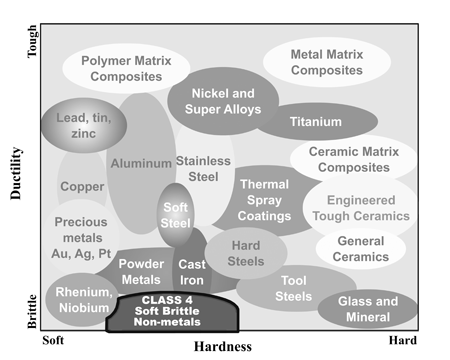

Aluminum Nitride Electronic Package

Specimen Preparation (Class 4 Procedures)

|

|

Ceramics such as alumina, beryllia (BeO) and aluminum nitride (AlN) are commonly used ceramics sustrate materials for metallizing because they provide thermal conductivity and electrical resistivity. The most common material used is alumina, however beryillia and aluminum nitride are used to improve performance at high frequencies.

The cross section preparation of electronic coatings and features on ceramic substrates can be very difficult because of edge rounding and phase relief. In order to maintain the integrity of the metallic layers the specimen must first be sectioned properly to avoid chipping and cracking of the ceramic substrate/ metal interface. Proper sectioning involves orientating the sample so that the coating is in compression (blade direction is into the coating and then into the ceramic substrate). It is also important that a fine grit diamond abrasive blade be used to minimize cracking and fracturing of the ceramic interface. Proper grinding is accomplished with as small a diamond abrasive as possible. Note there is a trade-off between planar grinding time (abrasive size) and induced damage. In some cases for ceramics, it is better to take more time and minimize damage at planar grinding in order to reduce overall polishing times. The use of SIAMAT colloidal silica also provides a chemical mechanical polishing (CMP) action which is the most effective means for eliminating both surface and subsurface damage. The combination of SIAMAT colloidal silica with DIAMAT polycrystalline diamond also produces the required surfaces finishes.

SECTIONING

Diamond Wafering blade - medium grit / low concentration

MOUNTING

Castable Mounting with Epoxy or Acrylic resins.

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

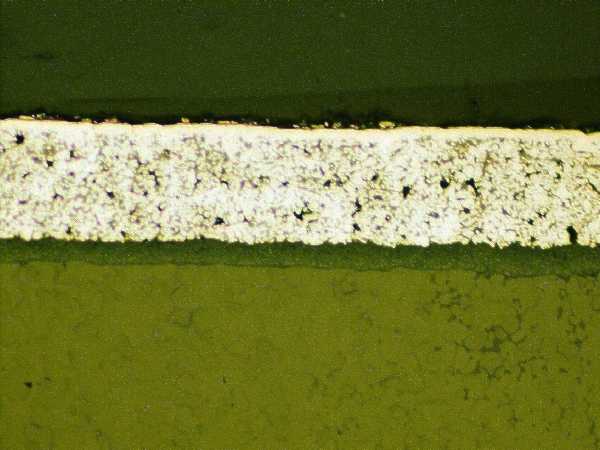

| AlN substate with a molybdenum/ nickel, gold coating

400X (B.F.) |

|

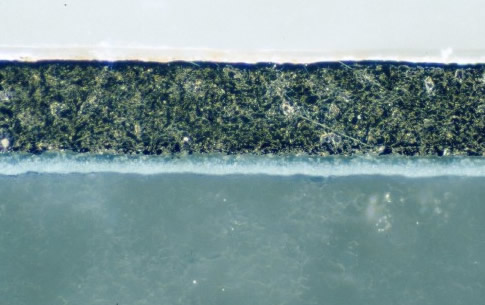

| AlN substate with a molybdenum/ nickel, gold coating

400X (D.F.) |

|

| AlN substate with a molybdenum/ nickel, gold coating 400X (DIC) |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com