|

|

|

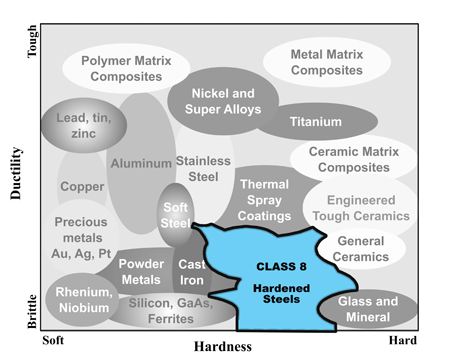

Heat Treated High Carbon Steel

Specimen Preparation (Class 8 Procedures)

|

|

Preparation of high carbon steels is fairly straight forward. Depending upon the heat treatment the grinding and polishing times may increase for the harder martensite structure.

SECTIONING

MAXCUT Abrasive blade (Cat. No. MAX-D or MAX-I series)

MOUNTING

Compression Mounting with Phenolic, Epoxy or Diallyl Phthalate compression mounting resins

POLISHING

*Required for central polishing force. Click here for more information on central vs. individual polishing force polishing.

|

| 1095 Steel, Furnace Cooled, etched with 2% nital, 400X B.F. Pearlite structure |

|

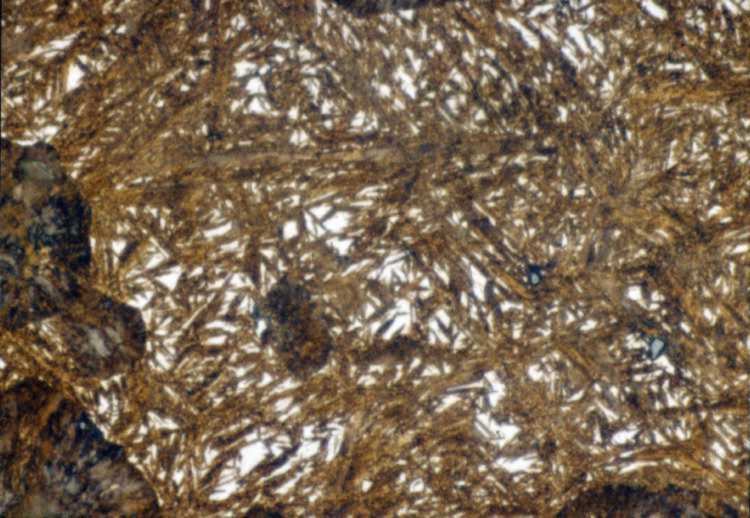

| 1095 Steel, Water Quenched, etched with picric acid, 1000X B.F. Martensite structure |

ETCHING

Common Etchants

CAUTION:Safety is very important when etching. Be sure to wear the appropriate protective clothing and observe all WARNINGS on chemical manufacuters SDS (Safety Data Sheets). Also review the COMMENTS and CONDITIONS Section for each etchant.

PACE TECHNOLOGIES CONTACT

PACE Technologies

3601 E. 34th St.

Tucson, Arizona 85713

+1-520-882-6598

FAX +1-520-882-6599

email: pace@metallographic.com

https://www.metallographic.com